|

Rapidly

Prototyped Cell Sorter

|

|

The

progress of microelectronics and microfabrication in the design of sensors

and actuators has provided us with the ability to create complete

integrated microsystems. These

systems are important applications to research in that they reduce the

cost and time of experimental procedures.

Cell separation has previously been done using large scale FACS

(fluorescence activated cell sorters) machines that are expensive, time

consuming, and very complicated to use.

The creation of a microsystem with a specifically designed array of

microchannels can be used to separate cells with much greater ease.

|

|

| The objective of the project is to optimize a

rapidly fabricated cell sorter. Rapid

fabrication deals with the creation of a complex array of microchannels in

PDMS using everyday materials and tools, rather than complex

microfabrication techniques used for MEMS devices and microelectronics.

Cell separation will be driven by electroosmotic flow.

This technique uses an electrical double layer that is formed when

a buffered cell separation array is placed in an electrical field.

|

| The

optimizational importance of the project is to design an array of

microchannels that will separate the cells with the least effort and with

greatest efficiency. The

following diagrams show the rapid fabrication method .

The following schematics shows the setup for electroosmotic flow. The system is similar to a capillary electrophoresis setup only in this case the capillary is the microchannel. |

|

|

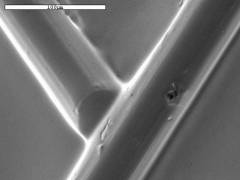

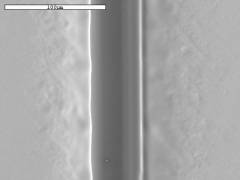

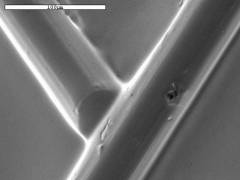

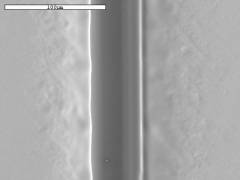

The following pictures are SEM pictures of

microchannels that were fabricated using the method described.

|

|

|

|

|

The motivation for the development of such a

system includes reduced

cost, time, reagent/analytes, and increased separation efficiency

portability, and provide analysis compatible to in vivo conditions.

|

|

For

more information:

Gill,

Amrit. Microfluidic Cell Sorter Concepts Using Rapid Fabrication

Techniques. Thesis. (2003)

|

|