PARTING ON THE LATHE

Introduction

Parting on

the lathe is simple operation in theory, but requires close attention to detail

for success. Failure to heed the

following tips can result in destroyed parting tools, ejection of the part from

the spindle, and permanent damage to the X-axis power feed on the lathe, so

when practicing, pay very close attention to what you are doing and have Mike

or a senior TA supervise the first time you try. For those who like to take notes as you read,

here’s

a condensed pdf version of this document.

Step 1: Part-off Tool Selection

As shown in

figure 1, there are generally two types of part-off or grooving tools: HSS and tungsten

carbide. As usual, HSS is cheaper,

tougher, and can be reground by hand once damaged. Carbide can tolerate much more heat, but once

the insert is damaged it must be replaced with a new one.

Figure 1:

HSS part-off tool (left) versus indexable part-off blade (center) and carbide

insert (right).

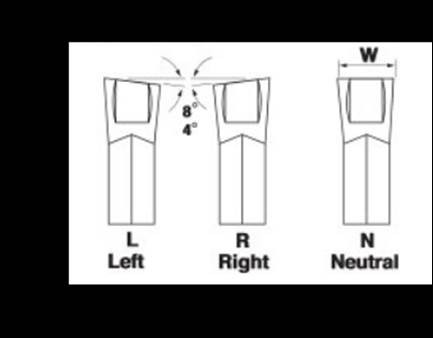

There are

many different styles of part-off inserts depending on the type of material

being cut and insert effectiveness. Most

styles are available in left hand, right hand, and neutral axial rakes

depending on where you want the inevitable little cylindrical “pip” to remain

(on the work clamped in the chuck or on the drop). In addition, carbide part-off inserts are

available with high temperature coatings for use cutting ferrous and abrasive

materials.

Figure 2: Carbide

parting inserts are available with different rake angles and coatings like titanium

nitride (TiN) for use cutting ferrous materials.

Step 2: Part-off Tool Inspection

Inspect the

parting tool closely before using. If

using HSS parting blades, grind and/or hone the cutting edge to ensure it’s

sharp. If using an indexable

part-off tool, check that the cutting insert is in good condition.

Figure 3:

Video on how to properly sharpen and use HSS parting blades.

Step 3: Maximize Cutting Tool

Stiffness.

Always

maximize cutting tool stiffness by minimizing the length the blade sticks out

beyond the toolholder block. For parting

larger diameters or stronger workpieces, it will be necessary to adjust the

stickout multiple times during the parting operation, as the tool cuts deeper

into the material. For the same reason,

always part-off as close to the chuck jaws as possible (typically within 1/8”)

to maximize part stiffness during parting, as illustrated in figure 7.

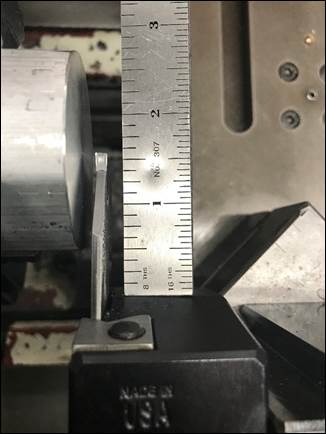

Figure 4:

Minimize the distance the part-off blade sticks out of the toolholder to

increase tool stiffness during parting.

Note the clearance between the toolholder and the part is also

minimized.

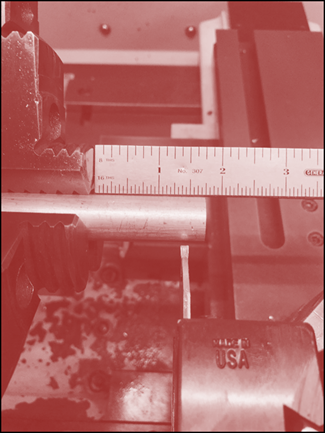

Figure 5:

Compared to Figure 4 the part-off blade is sticking out farther than necessary

for this 2” round stock, decreasing tool stiffness. The blade should be adjusted shorter.

Figure 6: To

adjust the part-off blade length for a particular cutting depth, use an Allen

wrench to loosen the screw in the back of toolholder which loosens the wedge at

the front of the toolholder and allows the part-off blade to be repositioned at

a different length.

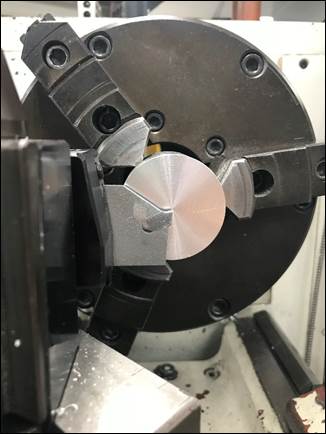

Figure 7: It

is better to perform part-off operations closer to the chuck (right) because of

the decreased deflection when parting. Within 1/8” of the chuck jaws is

preferable.

To function,

the part-off tool must be perfectly

aligned with the X-axis on the lathe.

This can be done several ways; the most common two are using a 1-2-3

block or a dial indicator, as shown in Figure 8.

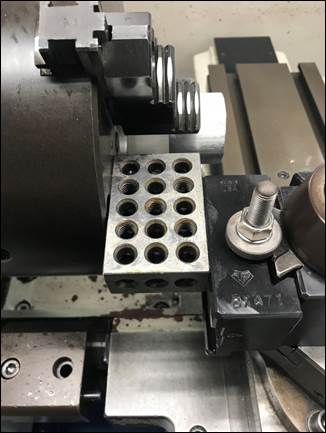

Figure 8: To

ensure the parting tool is perpendicular to the face of the chuck you can use a

1-2-3 block (whose surfaces are ground to be parallel to one another). Loosen the tool post, align the edge of the

toolholder flush with the 1-2-3 block, and re-tighten the tool post. Be careful to not drop the 1-2-3 block.

Figure 9: To

ensure the parting tool is perpendicular to the face of the chuck you can

alternatively use a dial indicator.

Attach the dial indicator to a Noga holder found in the metrology

cabinet, and place gently on the guideways (DO NOT slide the holder along the

guideway; simply set it down in place!)

Position the contact tip against the toolholder and move the cross slide

along the X-axis while checking to see the change on the indicator. +/- 0.001” over the length of the toolholder

or part-off blade is acceptable / desirable.

Step 5: Check and/or Set the

Vertical Height of the Tool

Like all

tools used on the lathe, the part-off tool height must be checked and adjusted

so it is as close to the vertical spindle centerline as possible. Never assume the tool is setup properly just

because it was in the lathe cabinet for the machine you’re using! If the parting tool is not on vertical

centerline it will fail to cut properly, and will be damaged in use.

Figure 10:

Just like the turning/facing tool, the parting tool has to on the vertical

centerline using the lathe gage (bubble level) or ruler technique.

Step 6: Feed by Hand with Lots of

Oil

When

parting on a manual lathe, NEVER use the automatic feed

(because you can’t feel poor chip evacuation like you can by hand), and be sure to use lots of oil because the

parting process has a wide width of cut and generates a LOT of heat. For this reason, the part will also be VERY

hot after parting.

Like

drilling, use pecks to break up the chips and apply more oil to the tip of the

parting tool.

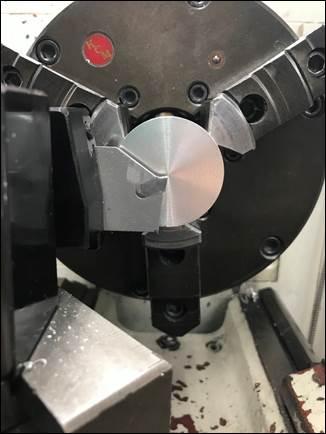

Figure 11:

Ensure that throughout the cut oil is being used to reduce the heat in the

cutting zone (left), if the chip starts to coil or “crunch”, back out of the

cut then reengage the workpiece. This

should break the chip (center). The parting

tool should leave a fairly smooth surface finish (right).

Part-off Surface Speed

When parting

on a manual machine, the parting tool should generally be run at approximately

60% of the recommended surface speed for the same workpiece/cutting tool

materials (like all manual machining operations). The Feeds

and Speeds resource document has an example of parting that will be

repeated here for convenience:

Calculate the speeds for

parting off 1” diameter aluminum and 1” diameter mild steel workpieces on the

lathe using a standard carbide part-off inserts.

First, lookup the recommended

surface speeds in Table

1 for a HSS part-off tool (VALUM

≈ 250 ft/min, VSTEEL

≈ 100 ft/min). It’s often better

to use the HSS value even when parting with carbide inserts on a manual machine

because parting is a problematic operation for inexperienced users.

Next, calculate the spindle

speeds:

NALUM [rpm] = 12 × V / (π ×

D)

= 12 in/ft × 250 ft/min / (π × 1 in/rev)

≈ 950 rpm

NSTEEL [rpm] = 12 × V / (π ×

D)

= 12 in/ft × 100 ft/min / (π × 1 in/rev)

≈ 380 rpm

Note: since applying oil

manually, scale the speeds back to 60%, so NALUM ≈ 570 rpm and

NSTEEL ≈ 230 rpm (final

answer). Note these are MAXIMUM

values and lathe chuck safety must take precedence; spinning the lathe chuck at

570 rpm is about the upper limit of what we safely do in the lab, so for

smaller workpieces, do not exceed 600 rpm, regardless of the calculation

results.

Catching Parts

Figure 12:

Parts with thru-holes can be safety caught using an undersized drill bit. NEVER try to catch a part by hand! Be careful not to run the part-off tool into

the drill bit. If there is no hole in

the part, place a rag under the part to soften its landing.

Here is a good video on parting tool

basics using HSS blades.