THREADING ON THE LATHE

Introduction

This

document presents some of the more common techniques for threading on the

manual engine lathe.

Using a tap

handle is the most common method of tapping on the lathe. The workpiece is clamped in the lathe chuck,

a spring

loaded center (for smaller taps) or a dead

center (for larger taps) is clamped in the tailstock, and the tap is held

and rotated using a tap handle, as we do with the assigned parts in lab.

Figure 1a:

Examples of using standard tap wrenches and spring loaded tap guide (left) or

dead center (right) to tap holes on the lathe.

Figure 1b:

Example of using an adjustable wrench and a live center to tap holes on the

lathe.

Figure 1c: Examples

of various tap handles.

Using a die

handle is a common method of external thread cutting on the lathe. The workpiece is clamped in the lathe chuck,

and the threading die is held and rotated using a die handle.

In

general, round-shaped dies are for cutting threads onto a workpiece and

hex-shaped dies are for chasing (cleaning up / repairing) existing threads.

Before

using a threading die it’s important to make sure the major diameter of the shaft

to be threaded matches the range listed in the Machinery Handbook. For example, a ˝-20 UNF 2A thread must have a

major diameter between 0.4906 and 0.4987”.

The smaller the major diameter, the easier the die will cut. In general, undersize the shaft diameter by

2% of the major thread diameter.

When

using a threading die on the lathe it’s important to start the thread die

collinear to the axis of the part, so use the body of the drill chuck for

alignment and guidance. It’s also

important to cut a generous chamfer on the end of the part to help the

threading die start cutting.

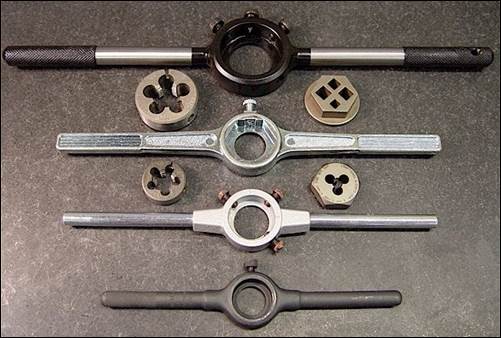

Figure 2a:

Examples of various threading die handles.

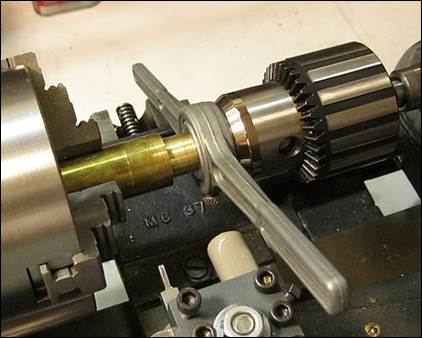

Figure 2b:

Using the drill chuck body to align the threading die axis with the workpiece

axis when starting the thread.

Rigid

tapping is the second most common method of thread cutting on the lathe. With this technique the tap or die is clamped

in the tailstock using a variety of methods and threaded into or onto the

workpiece under spindle power. Smaller

taps up to 3/8” can be clamped in a keyed Jacob’s style chuck (NEVER a keyless chuck!). Larger taps should be clamped using a split

sleeve or heavy duty tap driver, as shown in figure 3b.

Figure 3a:

Rigid tapping on manual lathe. Click the

image on the right for a

video showing the process.

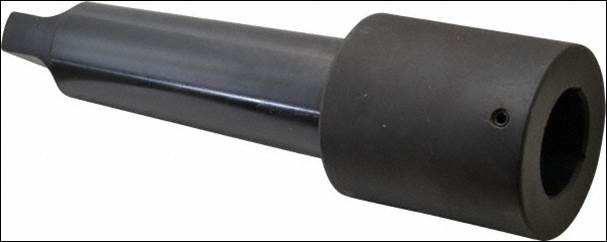

Figure 3b: Example

of split sleeve tap driver for lathe tailstock (left) and heavy duty tap driver

for lathe tailstock (right).

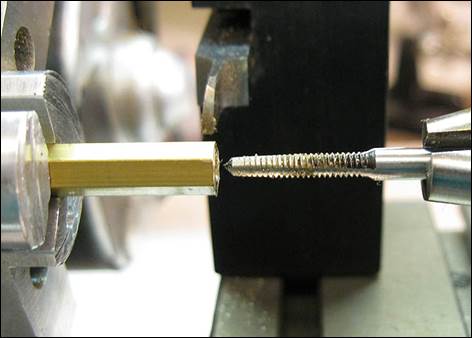

Figure 3c:

Rigid die cutting on manual lathe.

Die cutting

video

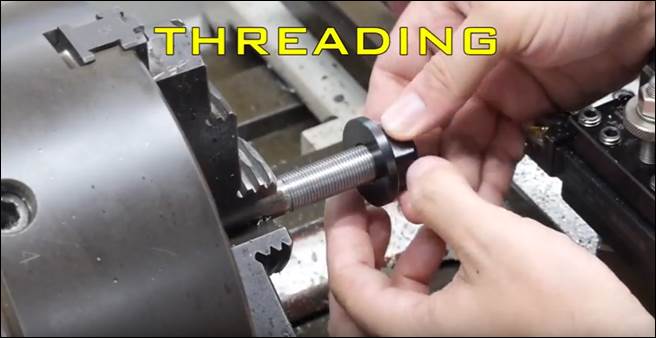

Single point

threading involves mounting a threading tool with the proper thread profile to the

toolpost and cutting the thread using multiple synchronized passes.

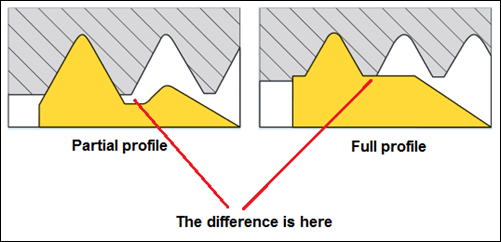

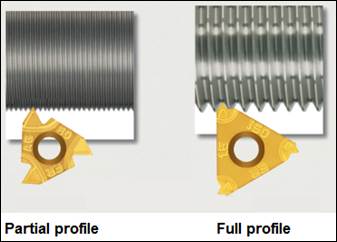

In general

there are two types of cutting tool geometries which can be used: partial and

full form profiles. Partial profile

cutting geometries only cut the minor (or root) diameter of the thread, whereas

full profile cutting geometries cut both the minor and major diameters of the

thread profile to size. The advantage of

partial profile cutting geometries is that one tool can cut a variety of thread

pitches, whereas a full profile cutting geometry is only good for one

particular thread pitch. The advantage

of full profile cutting geometries is that the entire thread is finished in one

operation, saving significant thread finishing and deburring time.

Figure 4a:

Partial vs full form profile threading geometries.

The

following videos explain the process in good detail. Fast forward through the parts which are not

interesting to you J.

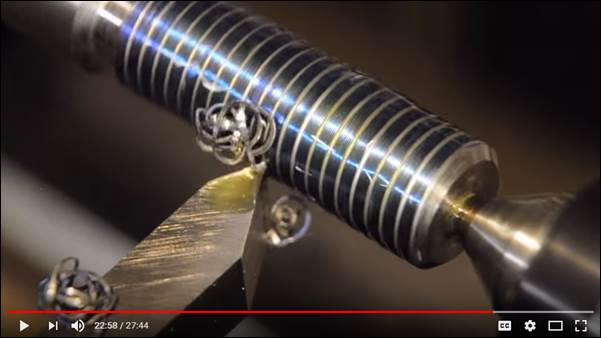

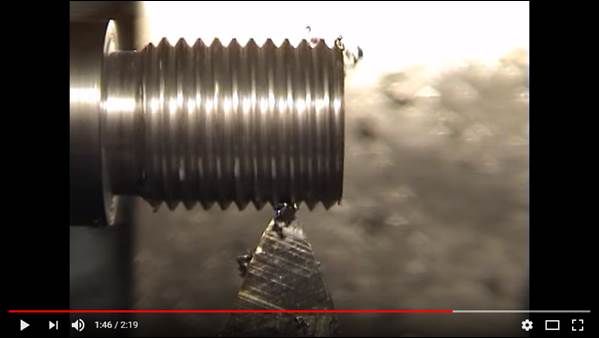

Figure 4b:

Good single point threading video (left; threading starts at 18:08 time stamp)

and shorter clip of thread cutting (right).

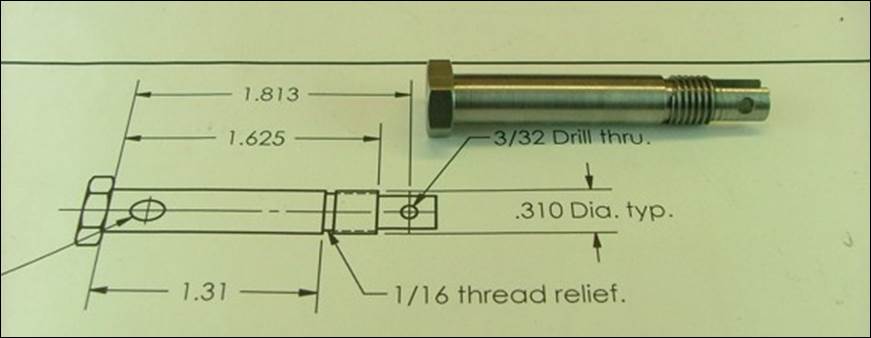

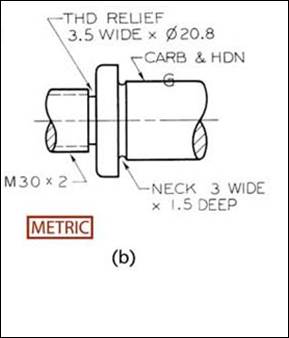

Figure 4c:

Examples of properly designed thread reliefs.

The process

for single point turning threads in the design lab is as follows:

1.

Clamp the

part in the lathe using a live center if necessary.

2.

Turn the OD

to the target major diameter and include a chamfer on the end at least 0.020”

smaller than the minor diameter of the thread profile to be cut.

3.

If

permissible, cut a thread relief using a grooving tool (as shown in Figure 10

and the two video thumbnail images above).

The thread relief should be slightly less than the minor thread

diameter.

4.

Adjust the

gearbox levers on the front of the headstock to cut the proper thread pitch.

5.

Adjust the

threading tool so

it is aligned parallel to the X-axis.

6.

Touch off on

the part and zero the X-axis.

7.

Cut a light

(0.001 - 0.002”) scratch pass across the surface of the part to be checked with

a thread gage for accuracy.

8.

If the pitch

of the scratch pass measures correctly, begin cutting the thread to depth;

start with deeper depths of cut (.010” in aluminum, 0.005” in steel) and make

progressively shallower cuts as the thread gets deeper and the threading tool

begins to leave a worse finish)

9.

As you approach

final thread size, use a fine file to carefully debur the rough edges of the

major diameter (unless using a full profile insert, which deburrs the major

diameters automatically, as discussed above).

The major diameter should end up a few thousandths of an inch under the

nominal size, according to the tolerances listed in the Machinery Handbook

(e.g. 0.4906-0.4987” for a ˝-20 UNF 2A thread).

You will know when you are close to the final size by keeping track of

your X-infeed value, which will end up smaller than the equivalent internal

thread’s minimum minor diameter by the noted allowance (e.g. 0.446” – 0.0013” =

0.4447” for the same ˝-20 UNF 2A thread).

10. The procedure for making an actual cut is:

a.

Check the

direction of the threading direction by engaging the half-nut with the tool a

safe distance from the part; for this example, we will thread toward the chuck

b.

Adjust the

spindle speed to a low setting (100-300 rpm) depending on how brave you are J

c.

Position the

tool in a safe starting location to begin cutting the thread

d.

Advance the

tool toward the part the distance (depth of cut) you wish to cut

e.

Engage the

half-nut for threading (it’s safest to leave this engaged for the duration of

the threading session)

f.

Turn the

spindle ON in the FWD direction and allow the tool to make a cut

g.

Turn the

spindle OFF before the tool reaches a shoulder (if not exists); you can use the

foot brake to stop it quickly if needed; if you stop too early, simply bump the

power switch to continue the cut or rotate the chuck by hand

h.

Retract the

tool a safe distance from the part in the X-direction

i.

Turn the

spindle ON in the REV direction to allow the tool to return to a safe starting

location

j.

Repeat steps

d. thru i. until the desired minor or pitch diameter is reached.

Figure 4d: Insert comprehensive single point

threading video here?

Threads can

be measured at least three different ways: by checking with a mating nut or

thread gage, by using a dedicated thread micrometer, or by using the three wire

method.

Mating Nut or Thread Gage

Checking

with a mating quality nut or thread gage is the easiest method to determine

when the thread is cut deep enough. Nuts

are much cheaper than calibrated thread

gages, but work fine for most prototyping applications.

Figure 5a:

Checking thread size using an existing, quality nut. It’s convenient to keep a complete set of

quality nuts on rings for thread measurement (right).

Figure 5b:

Checking thread size using a thread gage.

Click

the thumbnail for the video.

Thread Micrometer

Using a

thread micrometer is the easiest way to accurately measure thread pitch

diameter for comparison to the thread data listed in the Machinery Handbook or this link. However, thread mics are fairly expensive.

Figure 6a:

Example of a thread micrometer (notice the v-shaped anvils) and its use

measuring thread pitch diameter.

Figure 6b:

(Poorly made) video on how to use a thread micrometer. Click

thumbnail for video.

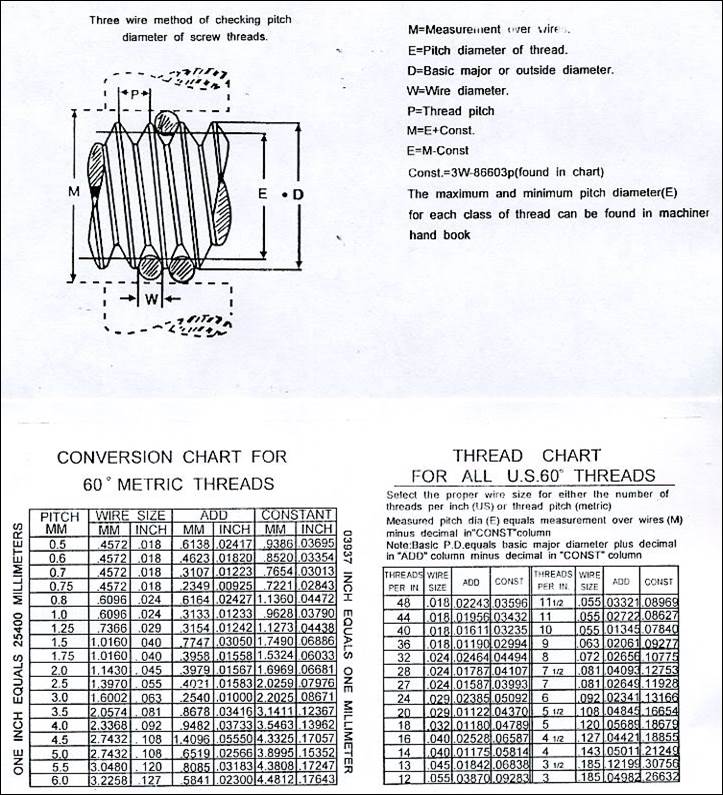

3 Wire Method

The three

wire method uses basic geometry and three identically sized wire rods to allow

the pitch diameter to be calculated using any standard micrometer

measurement. The three wire method is

very accurate and the cheapest method of measuring a variety of thread pitch

diameters. The downside to this method

is that it requires a lot of dexterity to make an accurate measurement without

dropping the precision thread wires.

Figure 7a:

Checking thread size using 3 wire method. Click the thumbnails for the videos.

Figure 7b: Thread

wire formulas for converting between actual measurement and pitch diameter.

Figure 7c:

Three wire measurement method explained.

Click

image for .pdf file.

Miscellaneous Points

Always

use cutting oil when threading on the lathe.

WD40 works well for aluminum. Oatey dark

threading oil works well for steel.

Chlorinated Moly-D works best for materials which are tougher to

machine, like stainless and alloy steels.