Materials and material selection

Table 1 presents a list of mechanical properties for common metals used by mechanical and aerospace engineers. The sections which follow discuss these materials and common applications of each.

|

Table

1: Approximate Mechanical Properties of Common Metals |

||||||||

|

Material |

Ultimate

Tensile |

Yield

Strength (psi) |

Modulus

of Elasticity (ksi) |

Elongation

at Break (%) |

Rockwell

Hardness |

Density

(lb/in3) |

Specific

Yield Strength |

Specific

Stiffness / Density) |

|

63,800 |

53,700 |

29,000 |

50 |

B71 |

0.283 |

190000 |

102000 |

|

|

58,000 |

36,300 |

29,000 |

20 |

B67 |

0.284 |

128000 |

102000 |

|

|

102,000 |

60,900 |

29,000 |

8 |

B95 |

0.284 |

214000 |

102000 |

|

|

78,000 |

60,000 |

29,000 |

10 |

B84 |

0.286 |

210000 |

101000 |

|

|

97,200 |

63,100 |

29,000 |

25 |

B92 |

0.284 |

222000 |

102000 |

|

|

230,000 |

205,000 |

29,000 |

10 |

C60 |

0.284 |

722000 |

102000 |

|

|

186,000 |

125,000 |

29,000 |

12 |

B100 |

0.284 |

440000 |

102000 |

|

|

319,000 |

277,000 |

29,000 |

12 |

C60 |

0.284 |

975000 |

102000 |

|

|

40,000 |

35,000 |

10,000 |

8 |

B45 |

0.097 |

361000 |

103000 |

|

|

45,000 |

40,000 |

10,000 |

17 |

B60 |

0.098 |

408000 |

102000 |

|

|

45,000 |

35,000 |

10,000 |

20 |

B60 |

0.098 |

357000 |

102000 |

|

|

83,000 |

73,000 |

10,000 |

11 |

B87 |

0.097 |

753000 |

103000 |

|

Steel:

Steel is a metal alloy consisting primarily of iron and

carbon (typically less than 2% by weight).

The carbon and other elements are used to harden and strengthen the iron

(as well as improve other material properties such as corrosion resistance),

allowing the metal to sustain higher loads without failure. As the carbon content rises, steel has the

ability to

become harder and stronger through heat-treating, but

this also makes it less ductile.

Regardless of the heat treatment, higher carbon content reduces weldability.

Low carbon (or “mild") steel (AISI 1018), is the cheapest metal available, making it the most commonly used type of steel. As seen in Table 1, mild steel has a yield strength around 50 ksi. Mild steel is used in a variety of applications from car doors to structural supports in buildings. Like all steel, 1018 has a density of 0.283 lb/in3 and a stiffness of 29,000 ksi, making it three times stiffer than the same size piece of aluminum. Figures 1 and 2 below show different structural steel shapes commonly available for manufacturing load bearing structures.

Figure 1: Various structural steel shapes. From L to R: square and round bar, tubing, channel, I or W beam, box tubing and angle shapes.

Figure 2: Structural steel beams welded together.

In sheet form, mild steel’s ductility and strength make it easy to bend or form into a variety of shapes. These properties, coupled with its high weldability, can lead to strong, rigid structural parts of relatively low weight despite the higher density of steel compared to other metals like aluminum or titanium. Examples are shown in figure 3 below.

Figure 3: Formed and welded sheetmetal fabricated parts.

Stronger steel alloys like 4130 and 4340 have yield strengths as high as 270 ksi and ultimate strengths surpassing 300 ksi. Interestingly, a metal’s density does not really change in relation to its strength, so all steels have roughly the same density.

Aluminum:

Aluminum is the most common metal in the earth’s crust, making up 8% of the earth’s surface by weight. Alloyed aluminum is a relatively soft, durable, ductile and malleable metal which is also easily machined. The density of aluminum is 2.7g/cm3 (roughly 1/3 that of steel); its lower density has led to its use in aircraft, automobiles and bicycle frames.

Aluminum is rarely used in its natural form for structural applications. The most common alloy used in industry is 6061, because of its relatively high strength potential. The 6061-T6 alloy has a yield strength of 40 ksi (around room temperature), and an elastic modulus of 10,000 ksi. Comparing these numbers to those listed previously for steel shows aluminum and steel have virtually identical stiffness-to-density ratios (as shown in table 1). Therefore, pound for pound, we can build just as stiff of a structure from steel as we can from aluminum! This is a common misconception among entry level engineers. The second common misconception is that aluminum is weaker than steel. It is true that the strongest alloys of aluminum are weaker than the strongest alloys of steel, but examination of table 1 shows the strongest aluminum alloys are stronger than the weakest steel alloys, so be careful making generalizations about the relative strengths of aluminum compared to steel.

The benefits of using aluminum suffer when discussing its weldability and cost. Aluminum has a thermal conductivity roughly six times greater than that of steel, leading to rapid heat dissipation that makes sustaining a molten weld pool more difficult than with steel. Do not misread this previous sentence as stating aluminum has poor weldability, but rather that aluminum has lower weldability than steel. Aluminum also costs ~20% more than the equivalent sized piece of steel; considering aluminum’s lower density, its cost is therefore approximately 60% greater per pound of material.

Figure 4: Fabricated aluminum car frame

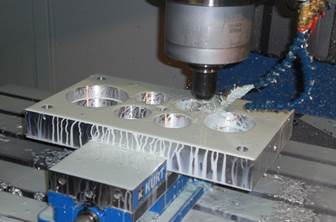

Figure 5: CNC machined billet aluminum parts

Sheetmetal:

Sheetmetal refers to metals with a high

ratio of surface area-to-thickness.

Sheetmetal fabrication can be a relatively quick and affordable way to

make brackets, hoppers, and manipulators.

Machining a thin-walled box from a solid block of material would require

significantly more time, and the material cost would be much higher because

most of the material would be converted to wasted chips. In this lab, there are three thicknesses, or

gages, of sheetmetal routinely stocked: 20GA, 18GA, 16GA

in both steel and aluminum.

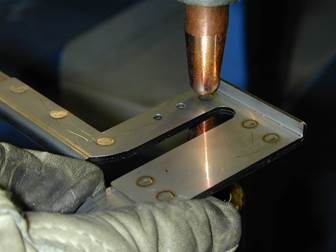

Common sheetmetal attachment methods

include rivets (semi-permanent fasteners), spot welding, and MIG (metal inert

gas) welding (figures 6, 7, 8).

Figure 6: Rivets used to join sheetmetal

parts

Figure 7: Spot welding used to join

sheetmetal parts

Figure 8: MIG welding used to join sheetmetal parts

Our lab has a nice graphical Sheetmetal Design Guide.

Plastic:

Plastics include a range of synthetic and semi-synthetic

solids made of polymers. The word plastic is derived from the Greek plastikos, meaning capable of being shaped or

molded. It refers to their malleability, which allows them to

be cast, pressed, extruded or machined into a variety of

shapes—such as plates, tubes, bottles, boxes and more.

Materials

in this category are not typically used in structural applications due to very

low yield strength and stiffness (less than 1/3 the strength of aluminum in the

case of PVC). However, many plastics

benefit from their low density and high machinability, making them useful for

constructing hoppers and ball sorting mechanisms, which see no significant

loading.

Figure 9: Various

plastic parts

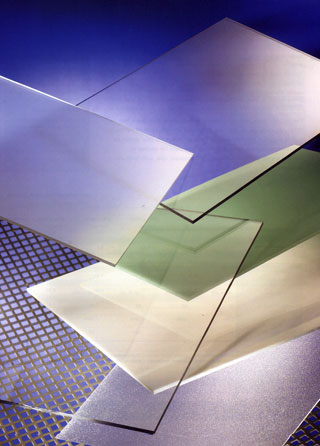

Figure

10: Plastic

sheets

Wood:

Wood

is a naturally occurring composite material; it is a hard fibrous tissue found

in many plants. Wood has been used for

thousands of years in building applications due to its low density,

availability and cost. Wood is readily

available in several forms including circular dowels and sheets (figures 11 and

12). The most common use of wood is in

the construction industry for framing walls and roofs. It is also used in the construction of boats,

furniture and flooring.

Wood

is not typically used in high precision applications because of the

irregularities caused by the grain structure.

Nor is it often used in high stress applications without adequate

additional support. As with plastic,

wood can be useful for constructing ball hoppers and sorting mechanisms because

of the moderate loads experienced in use.

Figure 11: A selection of wooden dowels.

Figure 12: Wooden structure (similar design methods would work for a ball hopper)

80-20:

80/20 is a rapid prototyping system made out of 6105-T5 extruded aluminum. 6105-T5 aluminum possesses a yield strength of approximately 35 ksi (see table 1), which makes it suitable for structural applications.

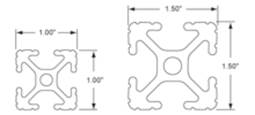

The many options that 80/20 offers has led to it being dubbed the “industrial erector set”. The unique cross section of 80/20 (illustrated in figure 13) greatly simplifies the assembly and disassembly of frame members because you do not need power tools to drill attachment holes. The t-slot functionality allows for infinite movement along the length of a piece and makes assemblies rapidly adjustable with common hand tools.

.

Figure 13: Profile sketch of 80/20 extrusions

The 80/20 available in lab is series 1010, which has a 1”x1” cross section and weighs approximately 0.5 lb/ft. Pieces of 80/20 can be rapidly attached using the angle brackets and ¼-20 fasteners as shown in this video. Figure 11 shows an example of two robots with frames constructed from 80/20.

Figure 14: Robot frames made from 80/20

Despite its benefits, 80/20 also has some drawbacks. First is the raw material cost. When compared to normal aluminum extrusion, the price per foot of raw material is about three times as much. However, much of this higher material cost is recouped with the lower manufacturing and assembly costs, since power tools and expensive machinery are not needed. Another drawback is that 80/20 is made from an aluminum alloy that is not weldable, so you are limited to using fasteners for attaching pieces together (as was the original intention of 80/20). Finally, while not necessarily a drawback, 80/20 limits you to using straight extruded pieces of material, as that is all that is available for use with this type of system, so you must design accordingly.

Here are some informative videos showcasing the versatility of the 80/20 system. If you elect to use 80/20 for your design project, you can get a lot of good ideas from these videos or from browsing the company’s catalog.