Wheels and tires for use in robotic applications

(pneumatic vs. plastic and regular vs. caster wheels)

While there is a huge variety of wheels available for a range of applications, they can be divided nicely into just a few groups. When researching wheels for robotic applications, it’s very important to choose a wheel that has a load rating that matches the approximate weight of your robot. In other words, you should not be researching wheels for full-size passenger cars for use on most robotics projects.

Regular vs. Caster Wheels:

For our purposes, wheel function can be divided into two common categories: regular wheels and caster wheels. In the simplest sense, regular wheels are cylindrical discs mounted on an axle or to a hub that rotate about a single axis. Figure 1 (below) shows a few examples of regular wheels. Regular wheels use either a center hole (like a bicycle) or a radial bolt pattern (like an automobile) to attach to a spindle or hub.

Figure 1: Regular plastic wheels

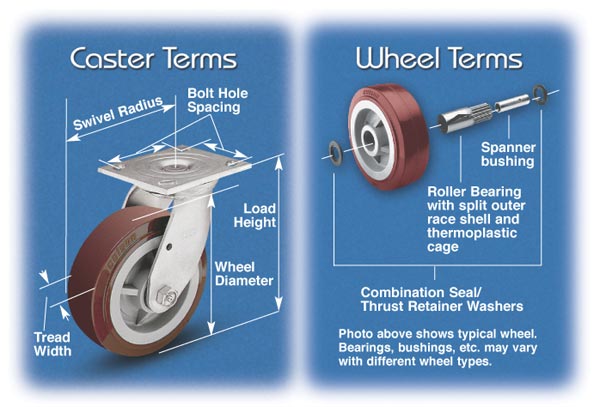

Caster wheels have their own mounting axle and are typically free to pivot about a second (near) vertical axis, as shown in figure 2.

Figure 2: Caster wheel terminology

Caster wheels are usually used on the non-driven end of a robot with differential steering to allow easy rotation of the mobile platform. Caster wheels are never powered and are available in a large variety of sizes and wheel materials. They are commonly found on grocery carts at the supermarket as well as office chairs and mobile furniture. Here’s a link showing a large variety of caster wheels.

Pneumatic vs. Semi-Rigid vs. Solid Wheels:

Both regular and caster wheels are available is a variety of types depending on the required load rating, friction coefficient and quality of ride. Each type is discussed briefly and illustrated with a few examples.

Semi-rigid wheels refers to assemblies that have plastic or hard rubber wheels and tires which are hollow but do not contain pressurized air. Semi-rigid wheels are commonly found on light duty equipment weighing between 20 and 100 pounds, such as push-style lawn mowers. Because of their light load rating and affordable price, these are the most common types of wheels used for the robotics applications in this course. The wheels shown in figure 1 are both of semi-rigid construction, as are the wheels shown in figure 3 below.

Figure 3: Semi-rigid wheels

Pneumatic tires (as shown in Figure 4) employ a rubber tire mounted to a separate wheel that is typically made from metal. Pressurized air is added between the tire and wheel to increase the load capacity. Common examples are found on bicycles, mopeds, and automobiles. One advantage to this type of tire is that, if damaged, only the tire usually needs replacement as opposed to replacing the entire wheel assembly. Another advantage is the air pressure can be adjusted to provide more traction, at the expense of load capacity.

Figure 4: Pneumatic wheels

Solid wheels refers to wheel assemblies that do not have hollow or empty space between the tire and wheel. These usually have higher load capacities than a similar size pneumatic or semi-rigid wheel; however, this comes at the disadvantage of a harsher ride. A few examples are shown in figure 5 below.

Figure 5: Solid wheels (regular type and caster type)