EML2322L / EML4502

Manufacturing Resources

This

webpage outlines various cutting tools available in lab and tips for their

selection and use. This

condensed sheet lists each tool size stocked in the lab for quick

reference. You are not limited to

these tools; however tools not on this list must be purchased prior to

manufacturing, as must tools for working with ferrous materials other than low

carbon steels (e.g. AISI 1018, or other 1XXX series low carbon steels).

Each section includes links to common vendors to purchase tools not stocked in

lab.

Table of Contents

Reamers & Precision Hole Making

Taps, Dies & Threading

Damaged / Stripped Fastener

Removal

Thread Repair

Drills & Rapid

Hole Making [RETURN TO T.O.C.]

Basics

of … Drills (Good Technical Info)

HSS

Imperial Center Drills (sizes and lengths shown in table below)

|

CENTER DRILL BIT

SIZES |

|||

|

Center Drill No. |

Body Dia. |

Drill Bit Dia. |

Drill Bit Length |

|

0 |

0.094 |

0.031 |

0.038 |

|

1 |

0.125 |

0.047 |

0.047 |

|

2 |

0.188 |

0.078 |

0.078 |

|

3 |

0.250 |

0.109 |

0.109 |

|

4 |

0.313 |

0.125 |

0.125 |

|

4½ |

0.375 |

0.141 |

0.406 |

|

5 |

0.438 |

0.188 |

0.188 |

|

6 |

0.500 |

0.219 |

0.219 |

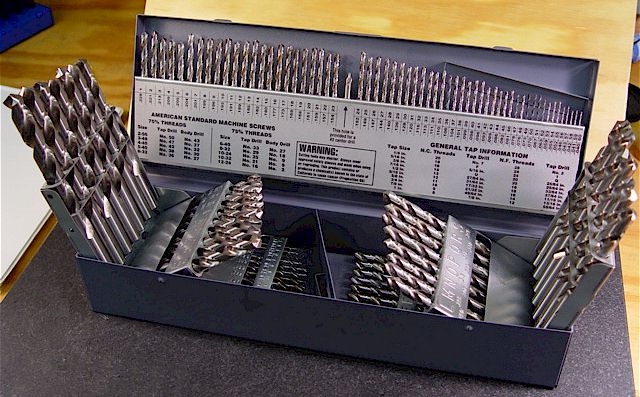

HSS

Jobber Drill Set Containing Fractional (1/64” – ½” by 1/64’s), Numbered

(#1-#60), and Lettered (A-Z) Drill Sizes

Silver

and Deming HSS Imperial Fractional Drills (9/16” – 1” by 1/64” increments, and

1-1/8” – 1-1/2” by 1/16” increments)

Metric HSS

Jobber Drills (1 – 6mm in 0.1mm increments, 6 – 13mm in 0.5mm increments)

Taper

Length (i.e. Long) HSS Drills (9/16” – 1” in 1/16” increments, 1-1/8” – 2” in

1/8” increments)

Extra-Long

HSS Imperial Fractional Drills (1/8” – 1/2” in 1/64” increments)

Comparison

of common drills from top to bottom: stub / screw machine length, jobber

length, tapered length, extra-long (aircraft) length

HSS Flat

Bottom Drills (1/64”-1” by 1/64 increments, and 1 1/8” – 1-1/2” by 1/16”

increments)

Process

Tip:

Always use a regular tapered drill to create the hole and only use a flat

bottom drill to finish it. In other words,

NEVER try to drill the entire hole with a flat bottomed drill, as doing so is

tremendously dangerous!

HSS

Sheetmetal Drills (3/16”-1/2” by 1/64 increments

Process

Tip:

Always use these drills in drill press or milling machine, as they are very

aggressive and can cause injury if used in a hand drill!

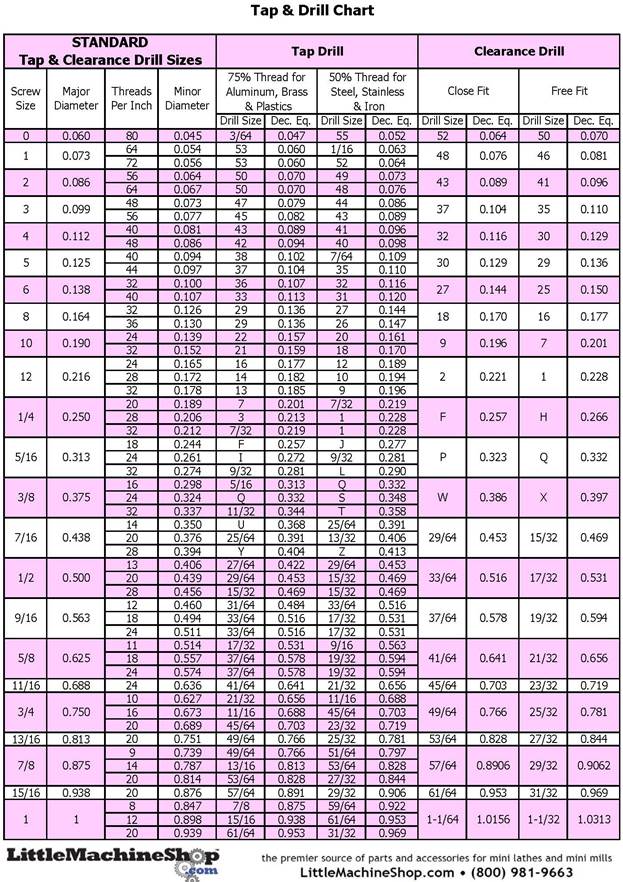

Imperial

Tap and Drill Chart (Click for PDF Version)

Imperial

Tap and Drill Chart (Click for PDF Version)

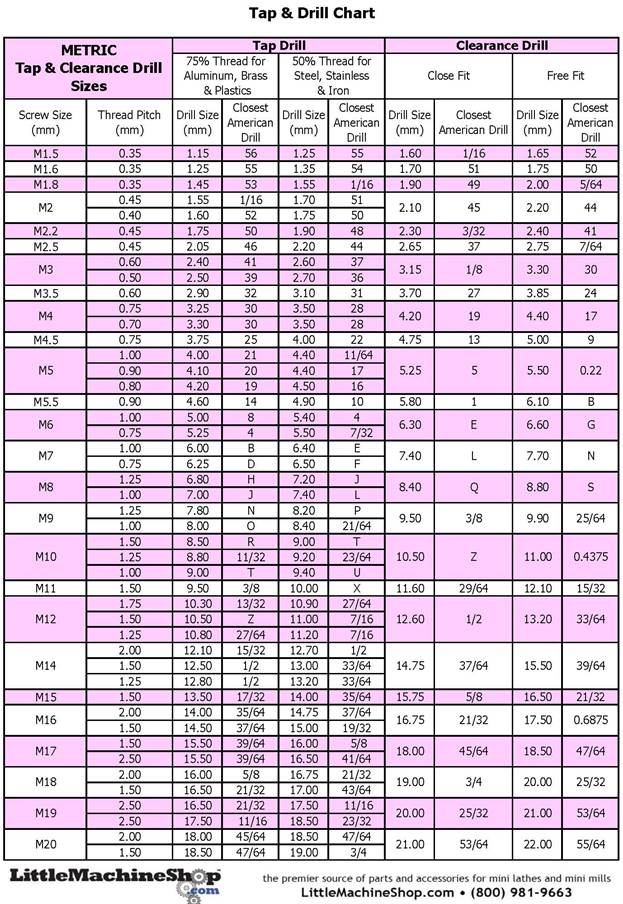

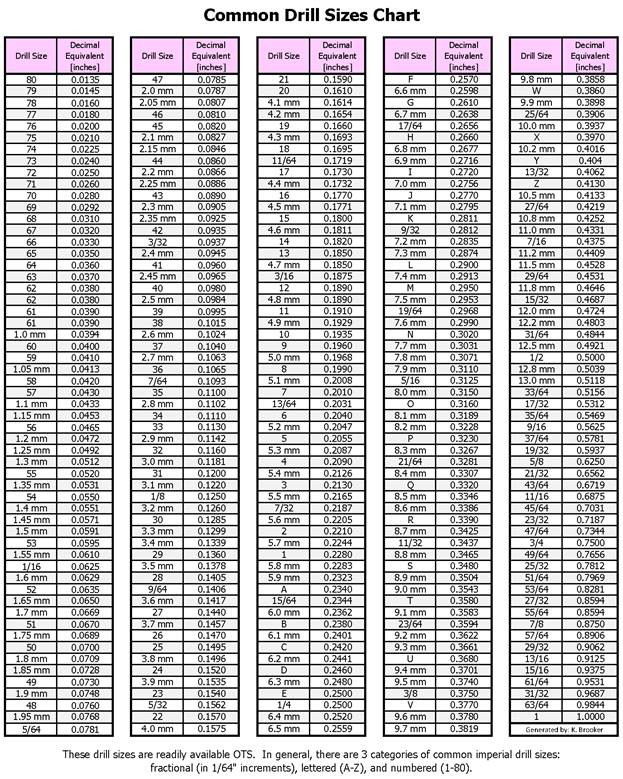

Drill

Sizes Chart (Fractional, Lettered, Numbered, & Metric) (Click for PDF

Version)

Annular

Hole Cutters (sizes 5/8” – 1-1/2” in 1/8” increments) and R8 Milling Machine

Arbor.

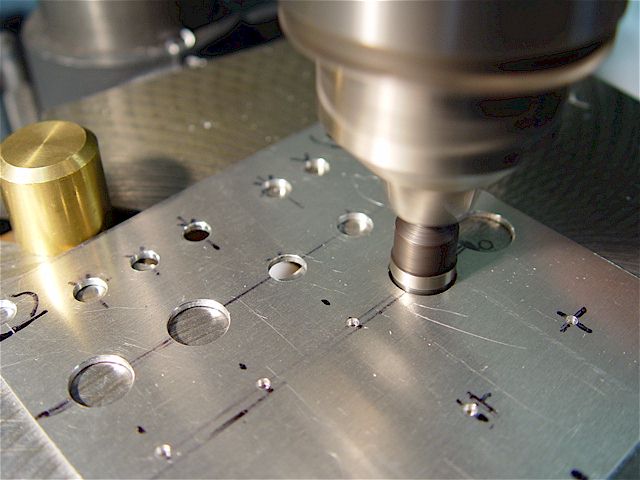

Annular

Hole Cutter In Use on Milling Machine (note the

annular groove it cuts through the workpiece, giving the cutter its name)

Stepped

Drill Bits for Creating Clearance Holes Thru Thin Materials (1/8” – 1-1/4” in

1/16” increments)

Reamers &

Precision Hole Making [RETURN TO T.O.C.]

HSS Reamers: Fractional (sizes 1/16” – ¼” in 1/32”

increments), Lettered (A – Z), and Numbered (#1 – #60)

HSS Reamers: Fractional Over and Under Sized (±

0.001” of the standard fractional sizes: 1/8” – 1/2” in 1/16” increments)

Reaming

Tips Reference Document

Process

Tip #1: When using reamers, leave 3% allowance for the reamer to remove. For example, if reaming a

Ø ¼” bore, drill the hole to 0.250” – 3% ≈ Ø0.243” in preparation for

reaming. The 1/64″ rule we use in

lab works pretty well most of the time for the holes we make, but 3% is the

standard.

Process

Tip #2: Reamers typically perform best at one half the speed

and twice the feedrate of the comparable size drill.

Process

Tip #3: Although reamers are by definition finishing tools, ALWAYS use

lubrication when using them in ANY material.

WD-40 works well in aluminum.

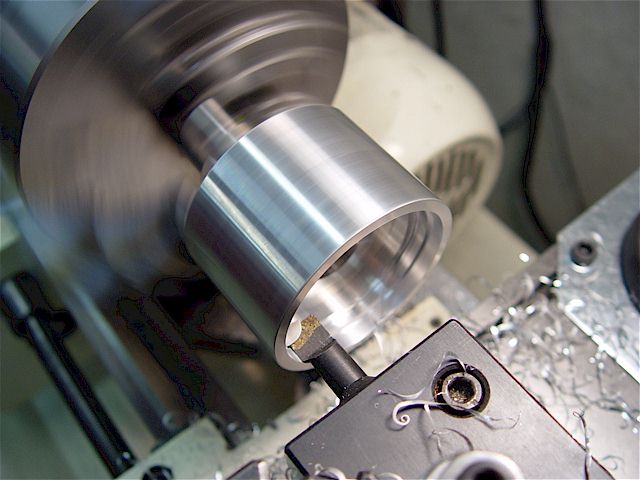

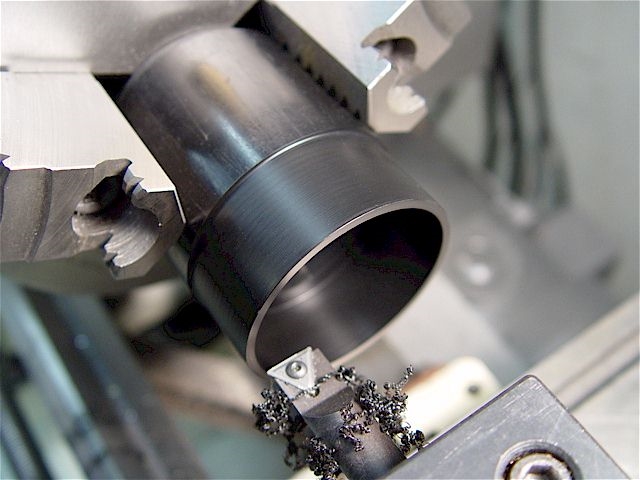

Brazed

Carbide Boring Bar Used on Lathe for Making a Precision Hole (± Ø0.0005”)

Brazed

Carbide Boring Bar Assortment (for 0.375” and larger bores in ferrous +

non-ferrous materials)

Indexable Carbide Boring Bar Used on Lathe for

Making a Precision Bore (± Ø0.0005”)

Indexable Carbide Boring Bar Assortment (for

0.375” and larger bores in ferrous + non-ferrous materials)

Process

Tip #1: When possible, drill the part to within a reasonable size prior to boring

because drilling in a much more efficient (i.e. faster) process.

Process

Tip #2: Indexable boring bar inserts have different sized corner radii. Larger corners are stronger and can take

deeper depths of cut. Smaller corners

are more fragile but produce better surface finish. The maximum depth of cut in our labs is twice

the corner radius of the boring bar insert.

Countersinks [RETURN TO T.O.C.]

Countersinks form a cone-shaped

opening at the top of a hole, which acts as a seat for the head of a screw or

rivet. They can also be used for chamferring,

deburring, and creating openings for holding material between centers.

Flutes

Fast Cut

— Have one flute and won't vibrate at high speeds. Also

great for cutting smaller holes.

General Purpose

— Have two, three, or four flutes. Tool life increases with more flutes

because the cutting load is distributed over more edges. However, fewer flutes

provide better chip clearance, which is a consideration when machining stringy

materials like plastic.

Smooth Finish —

Have six flutes. These remove more material per revolution and have a longer

tool life than other countersinks.

Body Diameter and Countersink Angle

The countersink body diameter must be equal to or larger than the head diameter

of the screw, center, or rivet being countersunk. Use a pilot hole that's larger

than 10% of the countersink body diameter.

Countersinks of various angles are

available for different purposes:

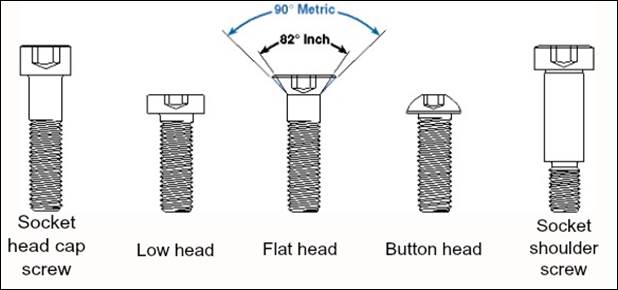

60° Countersink Angle: For

holding workpieces between the centers on a lathe.

82° Countersink Angle: For flat-

and oval-head inch screws.

90° Countersink Angle: For flat-

and oval-head metric screws. They're also great for chamfering.

100° & 120° Countersink Angles:

Primarily for rivets.

If ordering a countersink, a 90° countersink angle is likely the most versatile.

HSS Countsink Set (1/8” – 1” in size)

Counterbores [RETURN TO T.O.C.]

Counterboring— Enlarge

the top portion of an existing hole, forming a cylindrical-shaped opening with

a flat bottom that acts as a seat for the head of a screw or wood plug.

Shallow Counterboring—

Bore a shallow spot (1/8" or less) around a hole so that the head of the

screw, bolt, or nut is slightly raised above the surface of the material (also

known as spot facing).

Pilots— A

pilot guides the counterbore as it penetrates the

material, keeping it centered over the drilled screw hole and ensuring a level

seat for the screw head. Counterbores with

built-in pilots have a counterbore and

pilot made from one piece of steel. Changeable-pilot counterbores

have a removeable pilot, allowing you to use various

pilot diameters in a single tool.

HSS Counterbores (for #6 – #10, ¼”, 5/16”, 3/8”, 7/16”, and ½”

socket head cap screws)

HSS Counterbores (for M3 – M12 socket head cap screws)

An

example of three counter bores for a socket head cap screw (left)

Endmills [RETURN TO T.O.C.]

Basics of … Endmills (Good

Technical Info)

Endmill Nomenclature Figure 1

and Figure

2

Left to

Right: Flat-Bottom, Bull-Nose (aka radius cutter), and Ball-Nose Endmills

Flat-Bottom

(aka “Square”) HSS Roughing Endmills (sizes ¼” – 1” in 1/8” increments)

Flat-Bottom

(aka “Square”) HSS Regular Endmills (sizes ¼” – 1” in 1/8” increments)

Ball-Nose

HSS Endmills (1/8” – 1” in 1/8” increments)

Bull-Nose

HSS Endmills (1/4” to ¾” in 1/8” increments, 0.015”, 0.030”, 0.060” corner

radii)

HSS

Milling Cutters (Left to Right: Dovetail cutter, woodruff cutter, 90°

double-angle cutter)

Process

Tip #1: Create

a slot wider than the shank diameter of the cutter and as deep as the desired

feature.

Process

Tip #2: Use

the spindle speed equal to that of a comparable size endmill.

Video illustrating use of

Corner Rounding Endmills

Corner

Rounding HSS Endmills (1/16” – ½” radius in 1/16” increments)

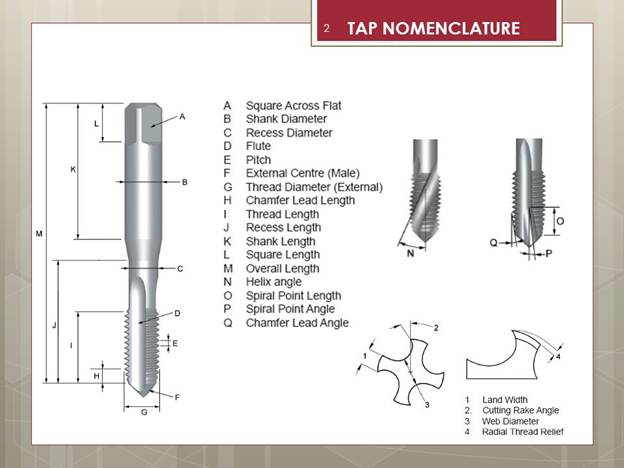

Taps

& Dies & Threads [RETURN TO T.O.C.]

Basics

of … Taps (Good Technical Info)

Types

of Threads (Unified National, Whitworth, Buttress, etc.)

Straight

vs. Spiral Flute Taps and Regular vs. Spiral Tip (aka Gun) Taps (1)

Straight

vs. Spiral Flute Taps and Regular vs. Spiral Tip (aka Gun) Taps (2)

Pulley

Taps and Extension

Taps

STI

(Screw Thread Insert) Taps

HSS Hand

Taps & Dies (#4 to 1” taps & dies; M4 to M12 taps; M4 to M25 dies)

Common

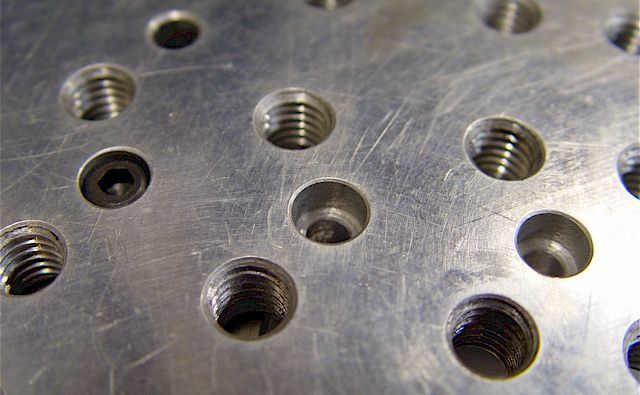

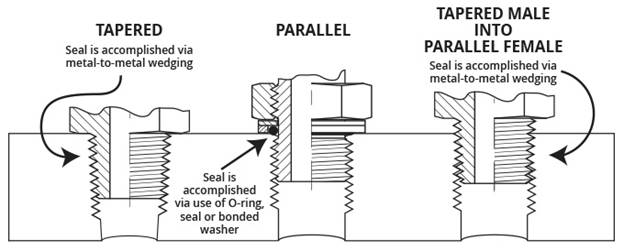

Types of taps: Taper Tap (for starting holes in hard materials), Plug Tap (for

starting holes in easy-to-machine materials), and Bottom Taps (for cutting

threads close to the bottom of blind (i.e. non-thru) holes)

Tapping

Station for Creating Threads Perpendicular to Workpiece Surface

Spring Loaded

Tap Guide for Creating Threads Co-Axial to Workpiece Centerline

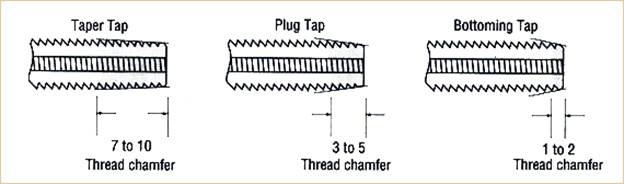

National

Pipe Threads (NPT) Male and Female Taps and Dies (sizes 1/8” to ¾”)

Thread

Gages for Identifying Unknown Imperial or Metric Threads

Instructional

Video on Identifying Thread Pitch and Size

Instructional

Video on Measuring Thread Pitch Diameter Using Thread Wires

Damaged / Stripped

Fastener Removal [RETURN TO T.O.C.]

Braddock Rule #8: Where there are fasteners

and co-workers, there will one day be damaged fasteners! Unfortunately, history proves this statement

correct, so good design engineers should know how to (1) not damage fasteners

when using them and (2) how to repair fasteners damaged by others who didn’t

know better. Read on if you want to be

that fastener guru who impresses your bosses and coworkers with your fastener

removal prowess J.

Before

we talk about some common procedures and tools for removing damaged fasteners,

let’s talk about how they get damaged in the first place; or better yet, how to

NOT damage fasteners when using them.

The

leading cause of fastener damage is ignorance regarding the proper tools for

use installing and removing them. And

with so many crappy tools and false marketing nonsense, it’s not surprising

that most people are confused. So let’s

discuss what we need to properly install and remove fasteners, as well as some

things that may not be common knowledge:

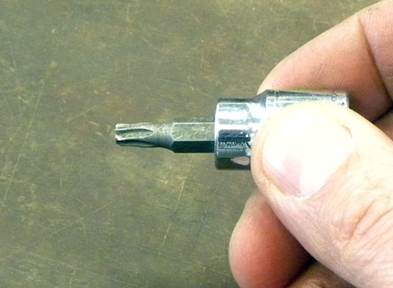

1.

Buy

good quality tools. If you buy the cheap

garbage at (gasp!) Walmart or Harbor Freight, you deserve to mess stuff

up! If you want to not damage everything

you work on, buy a quality set of screwdrivers, L-shaped hex wrenches, L-shaped

torx wrenches, hex drivers, torx

drivers, impact driver, and torque wrenches.

Here is an

excellent overview of common hand tools.

Yes, this

will run anywhere from $500 - $1,000, so it’s not always feasible on a DIY-er budget, but rarely is the right way also the cheap

way. Starting with screwdrivers, quality

tools possess superior metallurgy, proper fastener engagement, and better

ergonomics. Did you know they make

screwdrivers with hex

bolsters for use applying extra torque with a wrench; with striker

plates and thru shafts for impacting with a hammer to break corroded

fasteners loose; with laser

etched tips to bite into the fastener head and reduce the cam-out effect;

with superior

ergonomics for everyday use; and with high

grip handles for use in greasy or wet environments?

2.

Hex

and torx drivers are included on the previous list of

required tools because it is not safe (for the user or the fastener!) to try

and apply large amounts of torque to fasteners using hand-held wrenches. High torque results in high stresses. High stresses are resisted by higher strength

materials. Higher strength materials are

produced by heat treating (cheaper) or forging (more costly). And heat treating increases a material’s

brittle nature. Could you imagine the

danger in applying a large force through a brittle tool when it breaks? The user would most certainly be

injured. Therefore, most hand-held hex

and torx wrenches are not strong enough to apply the

large loads needed to remove stuck fasteners, which is why we need to invest in

quality metric and standard hex

and torx drivers. In addition, hex and torx

drivers are the only way to install these types of fasteners with a torque

wrench, the use of which is imperative for proper installation!

3.

Most

people have not been taught hex wrenches are consumables and must be reground

(“retipped”) or replaced at frequent intervals due to

the incredibly high contact (Hertzian) stress applied

to the corners of the tips when placed in simultaneous bending and

torsion. The same applies for torx wrenches and drivers, except when these yield or wear,

they must be replaced (unless you want more practice extracting damaged

fasteners!).

Even

screwdrivers need periodic replacement due to wear and yielding (albeit, the

frequency is inversely proportional to the quality).

4.

Know

some fastener head types are inherently weaker designs. If you take a lot of things apart (an

activity that teaches invaluable design and assembly skills!), you notice

certain types of fasteners seem more susceptible to damage: button head hex,

low head hex, flat head (countersunk) hex, slotted head screws, etc. In the case of button head, low head, and

flat head hex fasteners, the broached hex is smaller and shallower than a

regular hex head fastener of the same size, which makes the head MUCH more

susceptible to yielding / stripping. In

fact, when properly torqued, low and button head socket cap screws are so much

weaker in this regard, it’s standard practice in

precision machine assembly to never reuse them!

5.

Know

some fastener head types are inherently easier to mix up, with disastrous

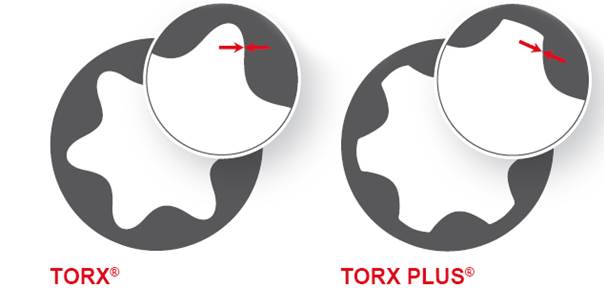

results; for example, torx

vs. hex, and torx vs. torx

PLUS!

6.

Never,

EVER, use a ball-end hex wrench to tighten or loosen a fastener. The ball end allows convenience off-axis

access to rotate the fastener, but high torque should never be applied using

one, because of the greatly reduced contact area between the major diameter of

the ball and the broached hex in the fastener head.

7.

Understand

cam-out and how to mitigate it. Cam-out

refers to the axial component of the reaction force created when you try to

torque a fastener. Stated another way,

when using a traditional screwdriver with a slotted or phillips head, the more torque you apply, the higher

the axial force becomes which tries to disengage the screwdriver from the

screw. There are many modern

developments in screw drives to reduce this cam-out phenomena, but it will likely continue to

exist in many of the fasteners you deal with in industry. The takeaway here is to apply as much axial force

as possible anytime you are applying a high amount of torque to a phillips or slotted style

fastener. The impact driver discussed

in detail below leverages this understanding of cam-out physics for its

benefit.

8.

Take

time to prepare hex head screws for removal.

During use it’s common for debris to pack inside the broached hex recess

in the fastener head. If you don’t take

time to remove that debris with a pick, the hex

wrench will not engage as much of the broached hex as possible, greatly

increasing the chance of stripping the head.

9.

When

taking apart fasteners you believe may be corroded or really stuck in place, ALWAYS

take the time to use an impact

driver to shock the fasteners and break them loose. Be careful, however, as these tools are SO

EFFECTIVE they will shear the head of a fastener right off if you set them to

rotate the wrong direction! Click the

previous hyperlink a short application video.

10. Always remember Side’s Rule #1: Your first shot’s

your best shot! Applied to

fasteners, put everything you learned above into action the next time you’re

asked to install or remove stubborn fasteners.

It only takes a little longer to do the things that are going to GREATLY

improve your chance of removing a stuck fasteners, versus spending ten times

longer trying to fix a fastener whose head you stripped.

Now

let’s talk about some common procedures and tools for removing damaged

fasteners:

1.

Often

an impact driver can be used to salvage the head of the fastener and break it

loose at the same time.

2.

Often

applying heat with an oxy-acetylene torch will cause the corroded fastener

joint to expand and contract enough (especially when used in conjunction with a

quality penetrating lubricant like PB

Blaster®), to cause the fastener to loosen.

This obviously only works on components that a little heat won’t damage.

3.

If

dealing with stripped

hex head fasteners, you have some good options.

The

cheapest option is to make sure the broached hex is clean and the driver /

wrench is in pristine condition (if not, simple retip

the wrench by grinding a bit off the end).

Next, you can try to file or grind a slight taper on the next larger

size wrench (std. or metric, don’t be afraid to mix in this instance; use the

size differential to your advantage), and hammer the driver into the damaged

hex. If using this option, employ a large

enough hammer to apply sharp impacts to the fastener head, which will help

loosen the threads (like an impact driver).

In a pinch, you can also try driving a quality (high strength) torx bit into what remains of the hex head, but this is

usually akin to a Hail Mary late in the game J.

Sock It Out, Inc. makes a commercial version

of these tapered removal tools (for standard and metric hex head fasteners as

well as torx) that make quick work out of removing

stripped hex fasteners (both cap screws and set screws) and torx

fasteners.

4.

If

dealing with fasteners that have sheared, or the head is simply not

salvageable, you have far too many options with which to waste your time, so

let me show you the two that commonly work J :

First,

are the ubiquitous spiral flute screw extractors, commonly called Easy-Outs. However, don’t

let the name mislead you, as the only thing easy about using them is snapping

them off inside the broken fastener you’re trying to remove! When using these (or any) extractors, it’s

imperative you drill an appropriately sized pilot hole through the CENTER of the

damaged fastener. The further the hole

is off center, the more likely the extractor is the break.

The second style works similar to the first,

however, instead of a reverse spiral, they are simply tapered square punches

which are driven into the pilot hole to lock into the damaged faster shank and

allow reverse torque to be applied. The

spiral flute extractors generally work the best, with the exception of left-hand

threads.

Thread

Repair [RETURN TO T.O.C.]

Corollary to Braddock Rule #8: Where there

are threads and co-workers, there will one day be damaged threads!

Unfortunately, history also proves this statement correct, so good

design engineers should know how to repair damaged threads. Read on if you want to be that fastener guru

who impresses your bosses and coworkers with your thread repairing prowess J.

1. Make sure

whoever you are trying to help with the repair understands you are not

responsible if it doesn’t work out. Far

too often a co-worker will try to fix their mistake before asking for help, and

their attempted fix makes your attempt at repair more challenging! In addition, some co-workers are happy to let

you share the blame for the damaged thread once you lay your hands on it, so

never try to help a co-worker you know is unprincipled.

2. Verify the

correct thread spec. Despite what anyone

tells you, it’s always good for verify the thread size yourself. If there are similar features on the part,

simply check another fastener, or gage another threaded hole.

3. Use a roll /

form tap to try and salvage internal threads by reforming them back to the

original profile. Using a cut tap will

further damage the thread, so don’t try it.

4. If the roll

/ form tap doesn’t fix the problem, and the threads are deep enough in the

part, you can sometimes drill out the damaged threads and use a longer fastener

which can engage more of the deeper, (hopefully!) undamaged threads.

5. If the threads

can’t be salvaged, it’s typically time to consider use of a threaded repair

insert. There are a few quality styles

on the market: EZ-LOKs,

Helicoils, Keenserts,

and Timeserts. Each work well in the proper application and

each have their drawbacks, as shown in these two good product comparisons: one and two.

Note it’s worth your time to research all of these

insert types, because they aren’t just used to fix damaged threads, but also in

many applications where higher surface hardness, lower contact stress, and

higher fatigue resistance are needed when placing thread in non-ferrous

materials. Helicoils

require special STI (Screw Thread Insert) taps, but are used widely in

aerospace applications (perhaps too

widely and for legacy reasons J ?).

EZ-LOKs are available in thin and thick wall versions, which provide

more options.

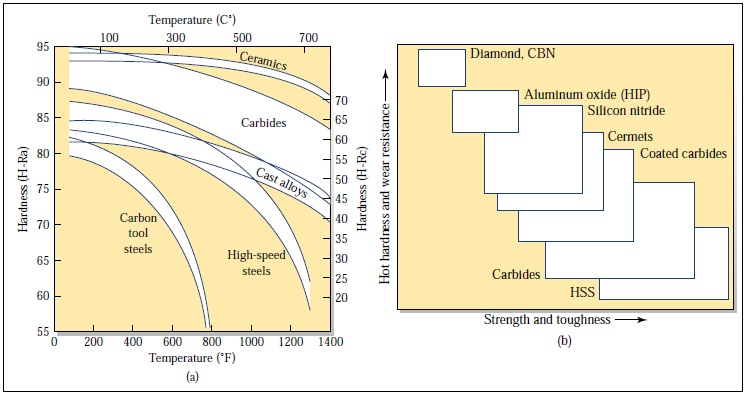

Cutting

Tool Materials [RETURN TO T.O.C.]

The

primary rule when selecting the proper cutting tool is that the tool material must

be harder/stronger than the workpiece being cut, or the tool will be damaged by

the material. On the

other hand, the stronger the tool material, the more brittle and expensive the

cutting tool. Therefore, much

like selecting workpiece materials, cutting tool materials should be selected

so they are harder/stronger than the workpiece being cut, but not unnecessarily

so.

There

are five categories of common cutting tool materials: high speed steel (HSS),

cast alloys (e.g. Stellite, Tantung, etc.), tungsten

carbides, ceramics, and cermets (ceramic

metals). Conveniently, high speed steel

(HSS) and tungsten carbide (WC) tools comprise over 90% of the modern cutting

tool market, so our discussion will focus on these two materials.

HSS

is the acronym for the most common grade of alloy steel used in the manufacture

of cutting tools. HSS offers good hot

hardness, which refers to its ability to maintain a sharp cutting edge as the

cutting tool elevates in temperature during the machining process. Cobalt can be added to the HSS alloy mix to

provide enhanced hot hardness. HSS also

possesses high toughness, which is the ability of the material to absorb a

significant amount of energy before fracturing.

For reference, the yield strength of HSS is around 45,000 psi. Common cutting tools made from HSS include

drill bits and reamers, endmills, taps and dies, bandsaw and hacksaw blades,

and lathe turning and facing tools.

WC is the abbreviation for tungsten carbide, which

is manufactured by sintering (baking) tungsten carbide powder with binders and

other additives to form solid carbide shapes which are often ground to final

shape. WC has similar properties to

ceramic: it can withstand extremely high temperatures and has a high

compressive strength (450,000 psi), but it is very brittle. WC tools can typically cut workpiece

materials at 2.5 times the speed of HSS, and they typically cost 2 to 5 times

as much.

Comparison

of Hardness & Wear Resistance vs. Strength & Toughness of Common

Cutting Tool Materials

Additional

information on Cutting Tool Materials

Cutting

Tool Coatings [RETURN TO T.O.C.]

Several coatings are available for cutting tools for

the purposes of providing high temperature thermal barriers and reducing the

friction coefficients between the cutting tool and workpiece materials. Since heat is the limiting factor for how

fast a particular tool can rotate when cutting a particular material, tool

coatings permit 15-30% higher cutting speeds, while adding about 10% to the

cost of the tool. Common coatings

include black oxide, titanium nitride (TiN), aluminum

titanium nitride (AlTiN), titanium carbonitride (TiCN), and

zirconium nitride (ZrN).

Coatings are generally not useful when tools are

used on manual machines because of the lower spindle speeds and the fact that

most tools will be damaged in use by accidentally feeding them too aggressively

as opposed to developing dull edges due to extensive use.

Common

Cutting Tool Coatings Applied to Finishing and Roughing Endmills

Harvey

Tool’s Excellent Tool Coatings Chart

Metrology [RETURN TO T.O.C.]

10:1 Rule – The resolution of the measuring

instrument should be ten times greater than the feature to be measured. For

example, if the length of a part is specified with a 0.005” tolerance, it must

be measured with an instrument with a resolution 0.0005″.

An

excellent quick guide to understanding errors in hand-held measuring

instruments can be found here

A

comprehensive guide to precision measuring instruments can be found here

Standards

Standards are

objects that have been certified by NIST to

meet certain dimensional accuracy targets. They are used as a reference for the

calibration of measuring equipment such as calipers, micrometers, and dial

indicators. There are several grades available: reference (AAA), calibration

(AA), inspection (A), and workshop (B). Since metals expand at a rate of

approximately 0.000010″/°F, all certification measurements occur at a

standardized 68°F (20°C).

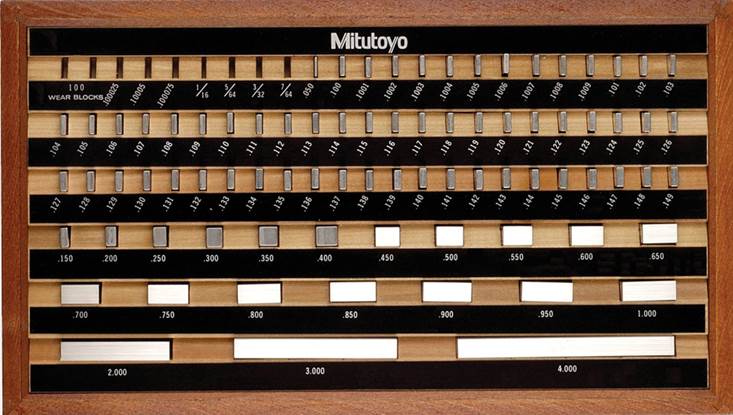

Gauge Block Set (accurate to ±0.000050″;

blocks can be joined with very little dimensional uncertainty)

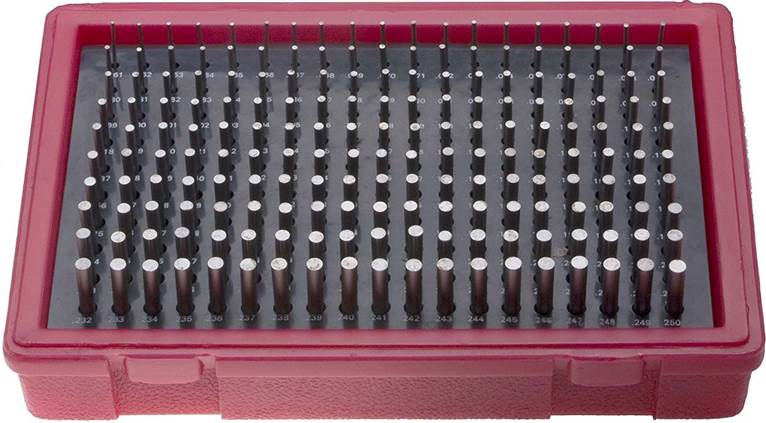

Gauge Pin

Set (accurate to ±0.000050″; may also be used to determine the size of a

hole to ±0.001″)

Micrometer

Standards (for setting the zero point of outside micrometers; 1″ standard

accurate to ±0.000050″; 5″ standard accurate to ±0.00015″)

Outside Measurements

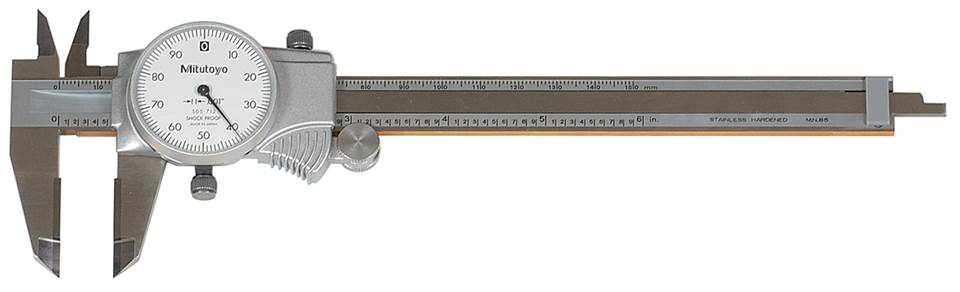

6″

Dial Calipers can measure outside, inside, depth, and shoulder measurements

·

Accurate

to ±0.001″ / ″ of travel; this error compounds linearly (i.e. a 6″

measurement taken with it is only accurate to ±0.001″)

·

Prone

to Abbe error, which says that a source of error is introduced anytime the

reference line of a measuring system doesn’t lie along the same line as the

dimension being measured

·

Prone

to parallax error, where the observed measurement changes depending on the

viewing angle

·

The

ID measuring jaws are offset from one another, which means the jaws will never

“find” the maximum diameter of the workpiece

·

No

way to limit applied pressure, resulting in a lack of repeatability and

reproducibility

·

Can

improve accuracy by calibrating with a standard that is close to the size being

measured

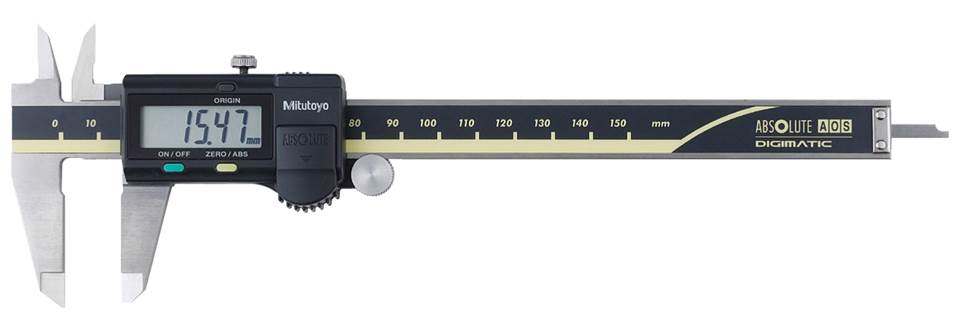

6”

Digital Calipers

·

accurate

to ±0.001″ over the entire 6″ range of travel

·

still

prone to each of the errors listed above, excluding parallax error

OD

Micrometers

·

accurate

to ±0.000050″

·

according

to 10:1 rule, can measure features to ±0.0005″

·

spindle

has a torque limiting ratchet or clutch to improve repeatability and

reproducibility

Set of

1-6″ OD Micrometers

·

each

micrometer has a range of 1 inch

·

set

includes 0-1″, 1-2″, 2-3″, 3-4″, 4-5″, 5-6″

micrometers

·

limiting

the travel of the spindle results in a more accurate measurement

·

any

quality micrometer will come with a standard that can

be used to zero the micrometer

Micrometer

Stand (used to hold micrometers to minimize heat input from the user and hold

the micrometer steady when measuring)

Inside Measurements

ID

Micrometers (accurate to ±0.0003″)

Dial Bore

Gauge (the dial indicator is zeroed at the desired measurement using a micrometer, and the relative displacement is used to

determine bore size)

Telescoping

Bore Gauge (the gauge has two spring loaded cylinders that are pushed into

contact with the interior of the bore and a locking mechanism to retain the

bore size once removed. A micrometer is then used to measure the bore gauge.)

Relative Measurements

Dial

Indicator (accurate to ±0.001 - 0.0002″ depending on indicator; shown

above measuring the straightness of a vise jaw)

Drop

Indicator (accurate to ±0.001 - 0.0001″ depending on indicator; shown

above measuring the concentricity of a part in a lathe chuck)

Other

Depth

Micrometer (accurate to ±0.0001″ for the micrometer head, varies per

measuring rod length)

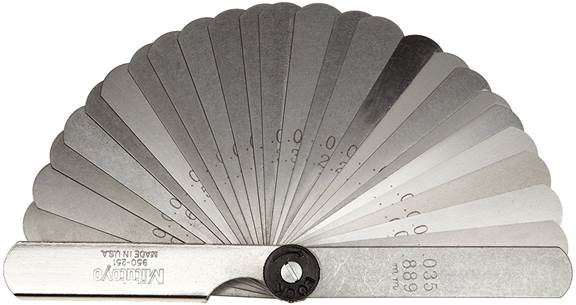

Thread

Pitch Gauge (used to determine thread pitch)

Radius

Gauge (used to determine the size of internal/external radii)

Feeler

Gauge (used to determine thickness, usually of a gap)

Electronic Measurement

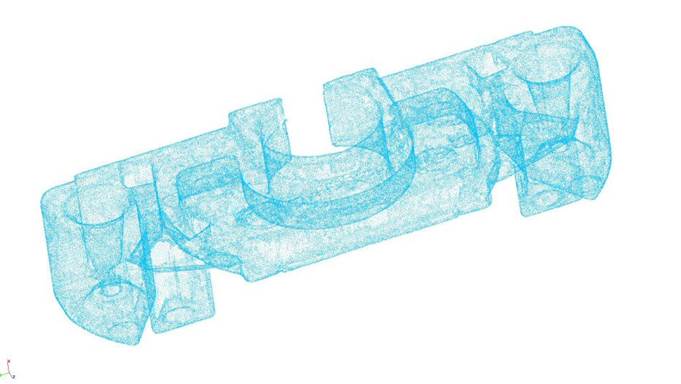

Coordinate

Measuring Machine (accuracy up to ±0.000015″; measurements are made with

a probe mounted on a multi-axis head)

Laser

Scanning (creates a point cloud of an object, high-end sensors can have a point

spacing of as small as 0.001″)

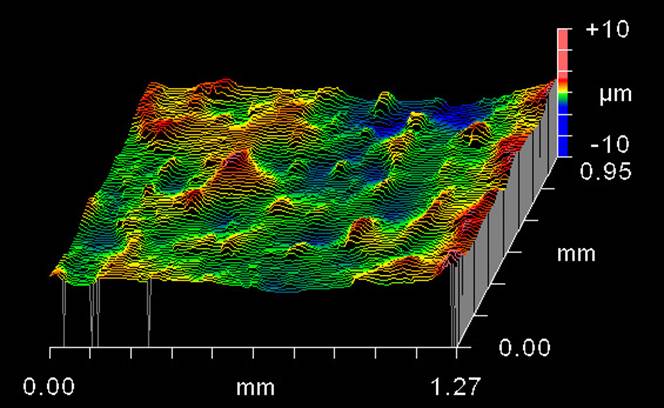

White

Light Interferometry (non-contact method for measuring surface profiles to

±0.000005″)

Photo copyright notice:

many of the photos and content on this page are taken from Micro-Machine Shop, which does an

excellent job organizing and presenting it.