Carl Wisniewski did not set out to create a sonic shock wave that students could touch, but he inadvertently created one as part of his UF MAE undergraduate honors thesis research. Wisniewski, a recent UF MAE graduate now enrolled in the MS program, sought an inexpensive means to characterize choked flow through throttle bodies, also called converging-diverging nozzles. This problem is relevant to Formula SAE (FSAE) racecar competitions where a fixed diameter circular flow restrictor caps engine power by limiting airflow. By rule, all competing teams must incorporate the same diameter air restrictor to keep races fair. So, maximizing efficiency of this orifice is pivotal to maximizing racecar powertrain output.

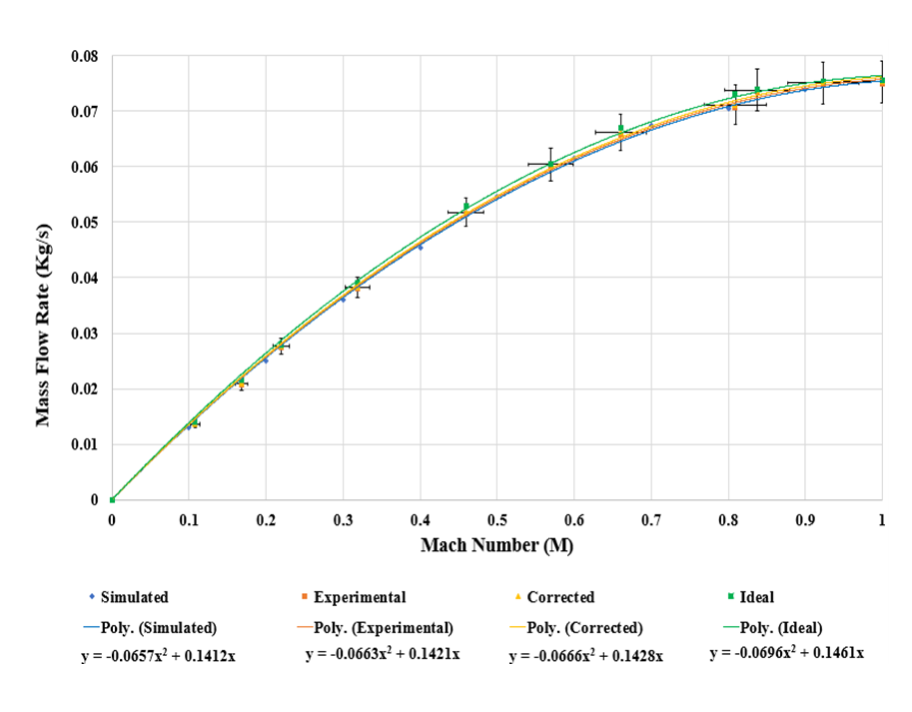

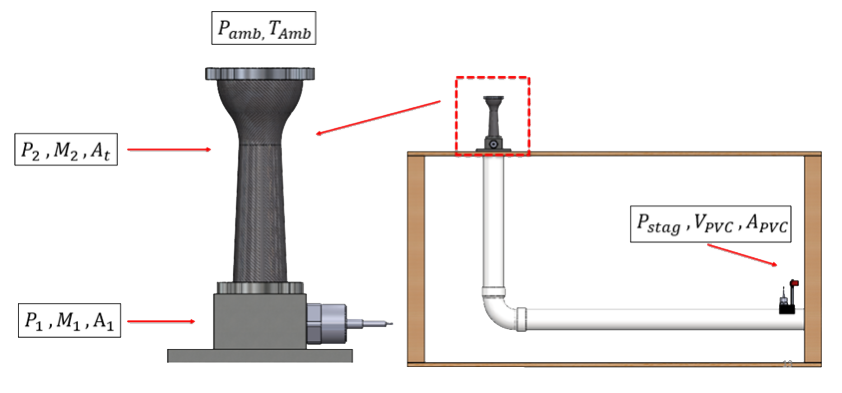

Most research of this type uses computational fluid dynamics (CFD) to optimize restrictor geometry, and practical validation is limited due to cost. To provide needed experimental confirmation, Wisniewski designed and built a flow bench experiment to measure air mass flow rates and orifice discharge coefficients at varying Mach numbers through a flow restrictor.

Wisniewski analyzed past CFD-driven restrictor design studies to underscore the importance of experimental validation. Leveraging CFD data, a C-D nozzle with optimized geometry was painstakingly fabricated from carbon fiber composite to minimize flow losses. But would it work in real life? To test performance, Wisniewski built a suction-style flow bench from PVC components with pressure sensors to facilitate nozzle flow measurement and analysis. A triad of common shop vacuums provided needed suction to draw ambient air through the flow restrictor. At a critical pressure, the flow choked in the restrictor nozzle, forming a shock wave – the maximum possible volume flow rate for this C-D nozzle. While experimenting with the bench, Wisniewski realized that students could reach fingers into the C-D nozzle mouth to feel the sonic shock front formed at the choke point; a novel and tangible experience buttressing the theory students learn in Compressible Flow class.

This work is featured in a paper Wisniewski will present at the American Society for Mechanical Engineering (ASME) International Mechanical Engineering Congress and Exposition (IMECE), the world’s largest interdisciplinary mechanical engineering conference, in October 2023. The paper is co-authored by MAE faculty Dr. Sean R. Niemi and Dr. Matthew J. Traum:

C. S. Wisniewski, S. R. Niemi, M. J. Traum, “A Sonic Throttle Body Characterization Flow Bench Adapted for Fluids Laboratory Instruction via Energy Engineering Laboratory Module Pedagogy,” IMECE2023-114300, Proceedings of the ASME International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, Oct. 29 – Nov. 2, 2023.

The experimental results compared closely with simulated and idealized data, revealing consistent agreement up to Mach 1. This research showcases the feasibility of created a low-cost experimental platform for precise testing and validation of C-D nozzle designs. The paper also outlines important instructional benefits for a budget-friendly C-D nozzle flow bench constructed using a modest budget. Wisniewski estimates the bench could be constructed by another college or even a high school for less than $500.