ME Capstone students are collaborating with Dr. Antonio Faciola, an associate professor of animal sciences at UF’s Institute of Food and Agricultural Sciences (IFAS), to redesign legacy cow digestion simulators pivotal for ruminant nutrition research. This interdisciplinary partnership leverages the Mechanical & Aerospace Engineering Department’s EML4502 course, taught by senior lecturer Dr. Matthew J. Traum.

In this course students are designing, building, testing, and evaluating a new benchtop apparatus for simulating ruminant digestion processes. Facilitating this collaboration is Engineer Stanley Pych from UF’s Chemistry Department, who contributes years of experience refining the electro-mechanical systems of the legacy cow digestion simulators.

“Simulating cow digestion with a benchtop experiment is challenging, and we are excited to bring animal sciences and engineering students together,” Dr. Faciola said. “Our students benefit by sharing expertise across academic departments, and UF is uniquely positioned to provide them this interdisciplinary collaboration opportunity.”

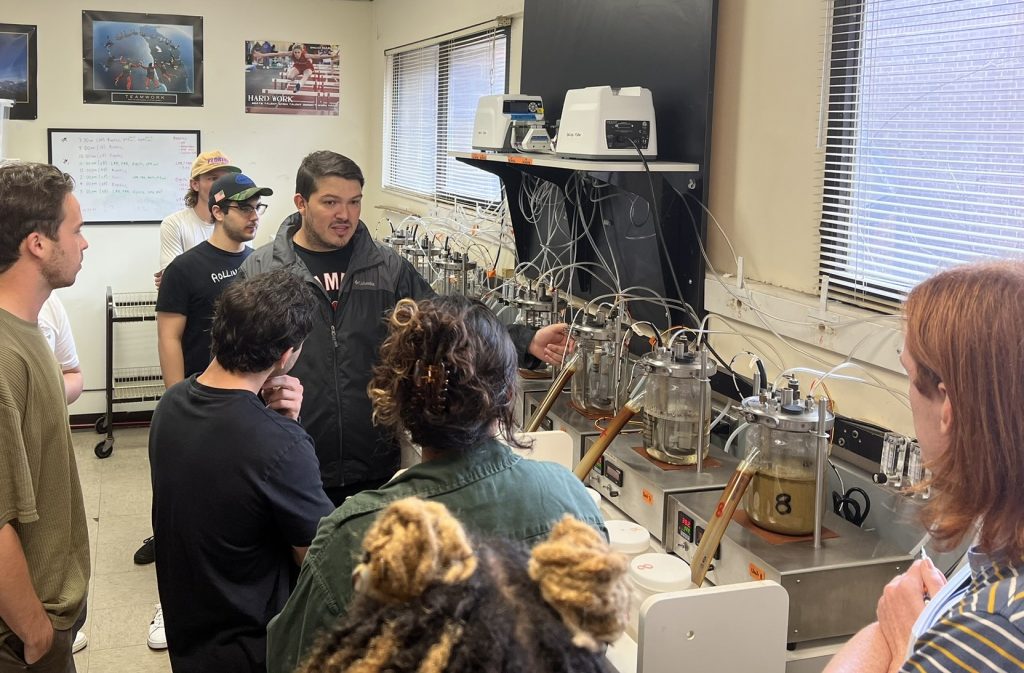

Fourteen ME senior design students visited Dr. Faciola’s lab, met with his graduate students, and observed legacy digestion simulators to gather critical details and facilitate redesign. The legacy cow stomach simulators from the IFAS Animal Sciences Department have been central to UF animal nutrition research, training undergraduate and graduate students, generating peer-review publications, and attracting many industry-university partnerships. These simulators are also critical to generate findings before live animal work is done. As these simulators are no longer commercially available, their continual maintenance and upgrading has become imperative.

The simulators operate by pumping artificial cow saliva into a slurry inoculated with IFAS cow digesta. The slurry is held in a transparent container, continuously agitated by a stirrer, and heated to 39 °C to replicate conditions of a cow rumen, the first of a cow’s four-compartment stomach. As ruminants, cow anatomy enables them to acquire nutrients by grazing on plants and fermenting them before digestion. Cows can digest plants that other animals cannot. The purpose of the digestion simulators is evaluating how different cow feed compositions impact various aspects of cow digestion including nutrition, digestion rate, gut microbial physiology, and methane greenhouse gas production.

“The combined thermal, mechanical, electrical, and biochemical elements of these cow digestion simulators make this project an ideal design problem for mechanical engineering students,” Dr. Traum said. “We look forward to collaborating with our IFAS colleagues with an eye toward spinning off what we create as an Ag Tech startup company.”

Dr. Traum noted that the scarcity of commercial alternatives for conducting cow digestion experiments presents a compelling business opportunity. IFAS uses its legacy digestor simulators continuously and receives numerous requests from other universities and agricultural companies to conduct experiments. According to the United States Department of Agriculture, cattle production is the most important agricultural industry in the U.S., worth $88.4 billion in 2023. The U.S. cattle head population, comprising both beef and dairy cows, reached 89.3 million in January 2023. Given the scale of the U.S. cattle industry and the potential to repurpose human food byproducts to feed these animals, studying cow digestion is of immense importance.

The first round of functional cow digestion simulators built and tested by ME Capstone students will be showcased by the end of the Spring 2024 semester.